TAKAYA APT-1600FD — 10 FLYING PROBES FOR UNBEATABLY FAST PRECISION

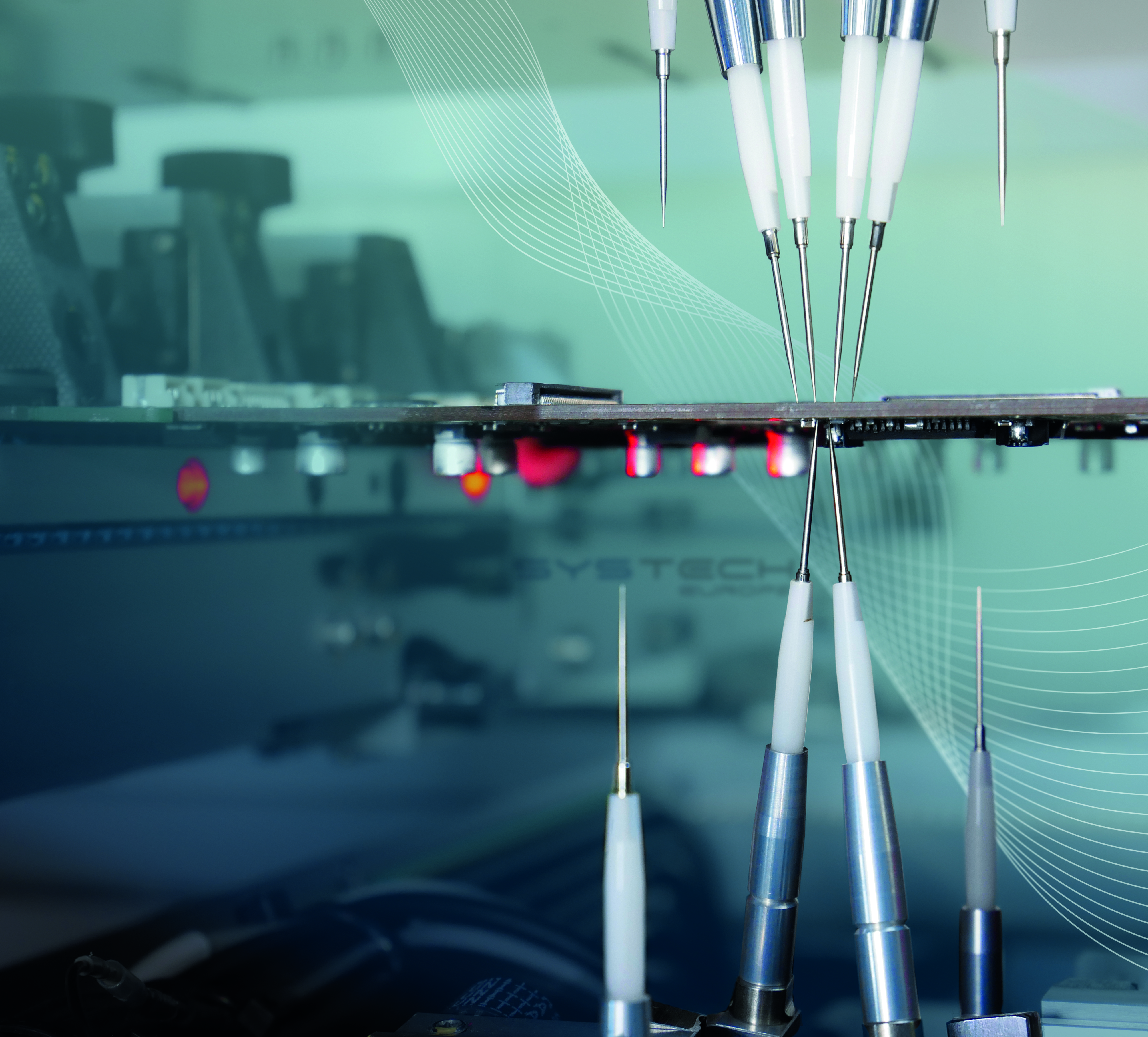

The TAKAYA APT-1600FD is the latest Flying Probe System from TAKAYA. It uses ten flying probes to inspect the PCB’s simultaneously from the top and bottom, has a laser height measurement system, uses cameras and LED sensors for optical inspections on both sides, and can considerably speed up the tests with signature analysis. The further improved test speed and the greater test coverage significantly expand the application possibilities of the flying probe test.

The mechanics from the top and the measuring electronics were taken over by the TAKAYA APT-1400F. Thus, the high precision, the contact reliability of the probes and the outstanding reliability were inherited. Depending on the PCB, significant increases in test coverage and productivity are the result.

THE HIGHLIGHTS OF THE APT-1600FD

DRIVE TECHNOLOGY AND MECHANICS (INCL. OPTIONS)

- Unique mechanics with 6 heads & 10 flying probes

- Ultra-fast XYZ motors and controls

- 50% faster than conventional flying probe test systems

- 25% more accurate, smallest contact area 60µm

- New design of axes and XY table in granite

- Highly flexible “Composite Robot” longlife measuring and control cables

- Soft touch control

- Measuring electronics directly on the probes

- Newly developed flexible PCB holder

- Transport system with automatic width adjustment and SMEMA interface

MEASURING DEVICE (INCL. OPTIONS)

- 16 bit DAC/ADC measuring device incl. 3 x DC 4-quadrant power supplies

- R, L, C measurements

- Measuring voltage < 0.1V

- Kelvin measurements

- Guard functions

- Diodes & zener diodes measurement functions

- Transistors/FET/optocoupler/relays/etc.

- DC/AC current and voltage measurements

- Voltage regulators/operational amplifiers/transformers

- Characteristic measurements of components and circuits

- Insulation measurements

- Continuity measurements

- Frequency measurements

- AC signal generator

- Cluster tests

- IC Open sensors

- LED tests (color and intensity)

- Laser for height measurements (warping and components)

- Net Signal Wave (signature analysis)

- Integration of external power supplies and test systems

OPTICAL SYSTEM (INCL. OPTIONS)

- 2 x high density CCD colour cameras

- 4 x LED ring light illuminations

- Position correction (offset, rotation, shrinkage)

- Detection of reverse polarity, missing, offset or incorrect components

- 1D and 2 D barcode recognition

- Character recognition

- Colour recognition of components

- Color Real Map function for graphical view of PCB’s and contact points